In this project, waste from street cleaning is recycled. For this purpose, the waste delivered to the plant is first stored in a material warehouse for dewatering. The recycling system is then fed from this material store.

Initial situation

Despite screening, the material still shows adhesions, so that recycling of the mineral components is not possible.

Objective

The objective of the BIBKO®-INFRATEC recycling system is to improve the quality of the recycled, mineral components through the wet-mechanical recycling process in the recycling plant to such an extent that reuse is possible.

Recycling process

The waste to be recycled is not fed directly into the recycling plant, but via a metering buffer. Material feed and material recycling are thus separated. This ensures a consistently high quality of the recycled material, regardless of the feed quantity and speed.

The dosing buffer is fed in two ways:

1. from material storage via excavators

2. from suction/flushing vehicles via feed hopper

The 2-chamber recycling plant type IT-5000/2 is continuously fed from the dosing buffer. By moving the waste through the pre-wash and main wash chambers, it is segregated, the mineral components >250 μm are washed and then discharged. The following figure shows the recycled material >250 μm after screening.

Process water recycling

Unwanted components and impurities are discharged with the process water. The impurities are first separated via an inclined belt filter. While the impurities are discharged via the belt, the process water enters the fines separation unit. In the fines separation, fines in the size range 60...≤250 μm are separated from the process water.

In the next step, the process water is conditioned in a 2-stage process:

- Stage 1: Heavy metal separation.

- Stage 2: Precipitation/flocculation.

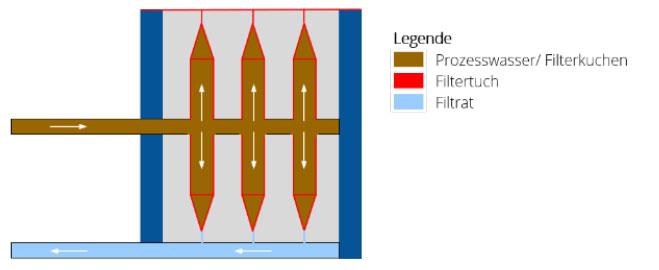

From conditioning, the process water enters a buffer tank. This serves as a feed tank from which the filter press is then fed. A membrane filter press is used as the filter press. After the filtration process, the filtrate is recirculated and reused in the recycling plant. On the other hand, filter cake is produced, which contains both fine particles ≤60 μm and the heavy metals and must be disposed of.

Chamber filter and membrane filter press in comparison

The dry substance content (DS content) of the filter cake in the chamber filter press is mainly determined by the pressure of the feed pump. The filter cake is only re-pressed by a corresponding pressure holding time at the end of the filtration process.

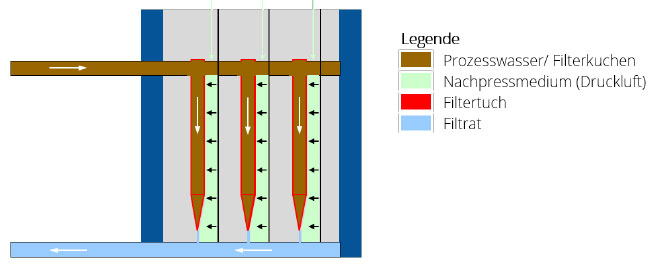

Membrane filter press

In the membrane filter press, the filter cake is again additionally compressed by a flexible, impermeable membrane after the charging process. This makes it possible to achieve a significantly higher degree of dewatering and thus a significantly higher dry substance content of the filter cake.