In this project, bentonite suspensions of different origins are recycled. For this purpose, the bentonite suspension is first buffered in a dosing buffer and then continuously fed into a 2-chamber recycling plant. While the mineral components >250 μm are discharged, the resulting process water with mineral components ≤250 μm is fed to a chamber filter press.

Bentonite suspension on deliveryBeginning situation

Bentonite suspension on deliveryBeginning situation

Material on delivery

Material Bentonite suspension

Delivery Suction truck (20 m³)

Density 1.22 kg/l

TS-content 30.0 %

Quantity max. 390 t/day

Material after recycling process

Material Process water

Density 1.07 kg/l

TS-content 10.3 %

Objective

The objective of the recycling system is to reduce disposal costs. This is done through the following steps:

- Reduction of the disposal volume through separation and discharge of the water contained (filtrate)

- Reduction of the disposal costs by generating a puncture-proof filter cake from the mineral components

Filtration process

The filtration process of the process water includes the following steps:

- Precipitation*

- Flocculation*

- Filtration

*The selection of the optimal chemical products as well as the determination of the dosage and the concentration is done in a preliminary test.

Process water light-grainyPrecipitation

Process water light-grainyPrecipitation

During this process, the bentonite particles contained in the suspension are destabilised.

Product Polyl solution

Manufacturer SEPAR-CHEMIE

Concentration undiluted

Process water flocculatedFlockung

Process water flocculatedFlockung

Nach der Fällung wird das Prozesswasser geflockt.

Dabei werden die suspendierten Bentonitpartikel zur besseren Filtration zu größeren Flocken vereint.

Produkt Wasserlösliches Polymer

Hersteller SEPAR-CHEMIE

Konzentration verdünnte Lösung

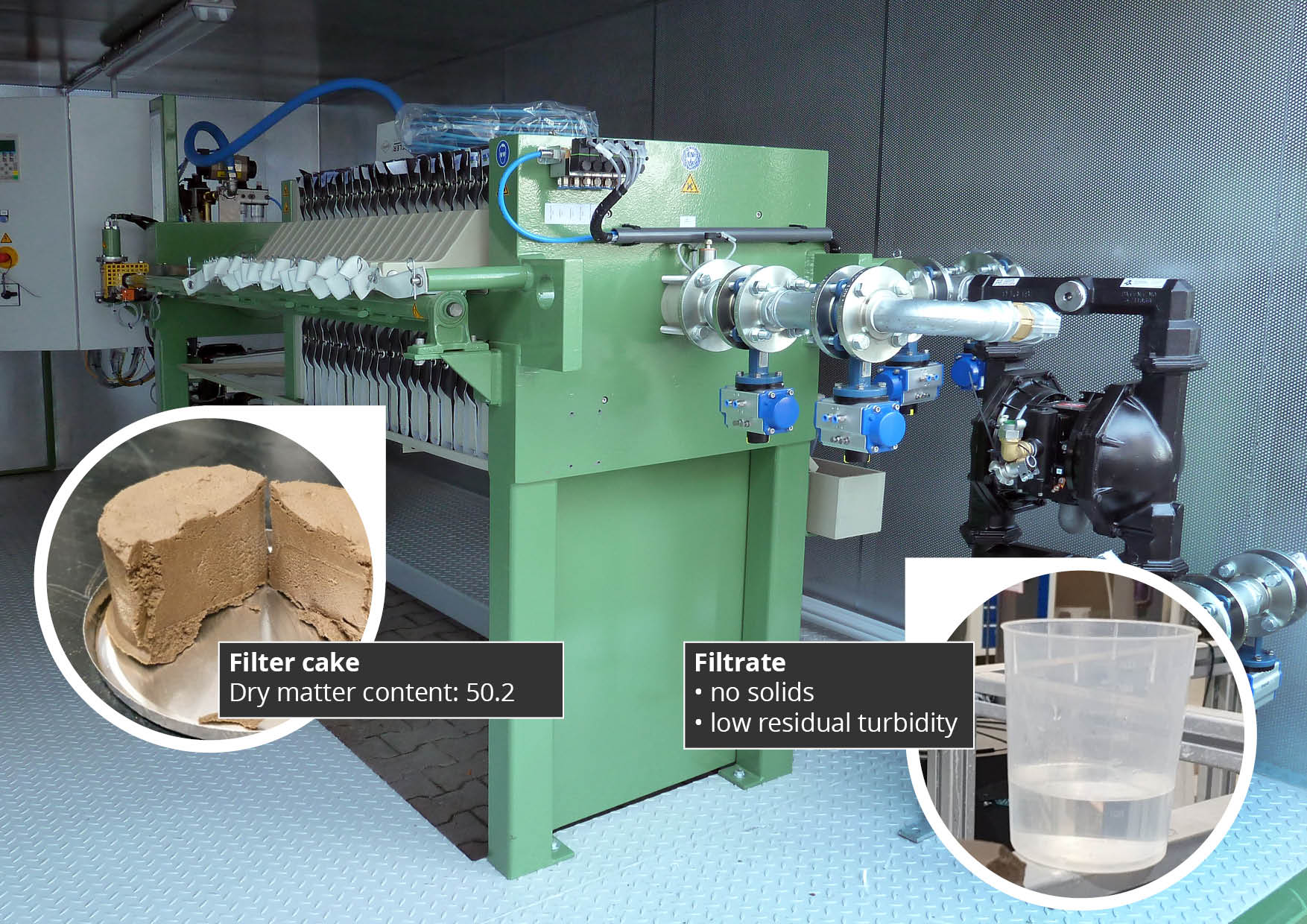

Filtration with chamber filter press

The next step is the filtration of the flocculated process water with a chamber filter press.

BIBKO® Filterpress

BIBKO® Filterpress

Membrane filter press as an alternative to the conventional chamber filter press

Compared to the conventional chamber filter press, membrane filter presses offer the possibility to further reduce the liquid remaining in the filter cake after the filtration process. This increases the dry matter content. For this purpose, the filter cloths are pressurised with air after the filtration process. The filter cloth is pressed against the filter cake, so that the filter cake is additionally dewatered.